- Home

- About Us

- Products & Services

- Plants

- Chemicals

- Infrastructure

- Research

- Media

- Reach Us

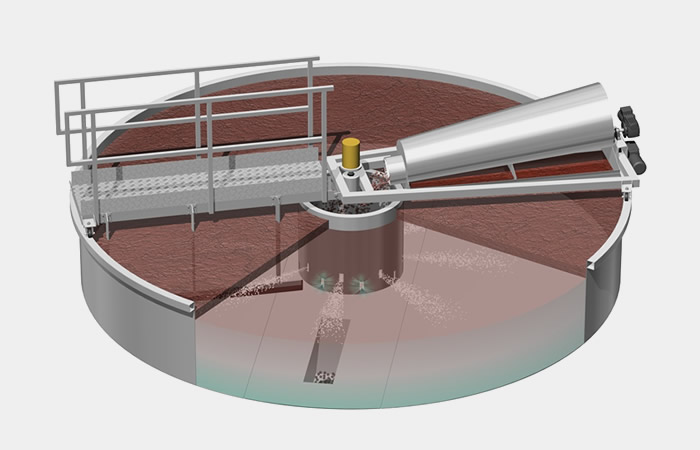

JHPL developed the slim and trim equipment for removal of Oil, Total Suspended Solid, Turbidity, COD and BOD. We design it to separate sludge and water in a single equipment. The equipment has small foot print area compare to other clarifier and conventional separator. The millions of micron sized air bubble mix with effluent & treatment chemical at elevated pressure, which float the sludge, oil and other impurity in fraction of minute. Our specialized conveying mechanism to remove the floated impurity in thick slurry and sent it to slurry tank for further process. The clarified water is passing through pressure send filter for further filtration.

Our tailor made separator is very flexible to handle wide range of effluent with minor modification in dosing of chemical and alteration in mechanical parts. We synchronize the operation of mechanical parts and chemical dosing to treat the typical effluents. System has inline pipe flocculator for addition of treatment chemical along with raw effluent before entering the separator. The treatment chemical breakdown the water, oil& dust emulsion and generate treated effluent. The generated sludge and oil will float on the surface of well with pressurized fine bubble of air. The floated sludge and oil be continuously removed by rotating Scoop attached with separator.

The advantages of DAF are their ability to treat a wide range of suspended solids in water at a high rate of solids removal and for wastewater sludge thickening. Millions of micron sized air bubbles in the thickener float solids to the tank surface, forming a concentrated sludge blanket. A scoop removes the thickened sludge.

We experienced the wide range of application in various industries and we can customize the equipment for specific purpose.