- Home

- About Us

- Products & Services

- Plants

- Chemicals

- Infrastructure

- Research

- Media

- Reach Us

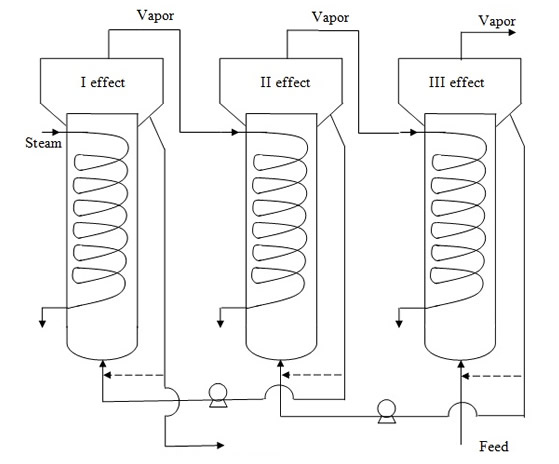

The chief factor influencing the economy of an evaporator system is the number of effects. By increasing the number of effects we can increase the economy of an evaporator system. The first effect of a multiple effect evaporator is the effect to which the raw steam is fed, vapors obtained from first effect act as a heating medium for another effect.

Different types of feed arrangement of multiple effect evaporators -:

In this arrangement the feed and steam introduced in the first effect and pressure in the first effect is highest and pressure in last effect is minimum, so transfer of feed from one effect to another can be done without pump.

In this arrangement the feed and steam introduced in the first effect and pressure in the first effect is highest and pressure in last effect is minimum, so transfer of feed from one effect to another can be done without pump.

In this arrangement feed is introduced in last effect and steam is introduced in first effect. For transfer of feed, it requires pump since the flow is from low pressure to higher pressure. Concentrated liquid is obtained in first effect.

In this arrangement feed is introduced in intermediate effect, flows in forward feed to the end of the series and is then pumped back to the first effect for final concentration. This permits the final evaporation to be done at the highest temperature.

Selection among the three configurations relies on variation in the salt solubility as a function of the top brine temperature and the maximum brine concentration. At higher temperatures or higher brine concentrations, scale formation takes place inside and outside the tube surfaces.

- Decrease of the available flow area inside the tubes, which causes increase in the pressure drop and pumping energy, and - Increase of the thermal resistance for heat transfer. This reduces the heat transfer efficiency, which results in a lower product flow rate.